There are times when you have to take your print advertising up a notch. Often times, what a printed material really needs is a unique appeal which traditional printing styles can sometimes lack. A metallic finish to your printed properties can give them the much needed ‘uniqueness’ and aesthetics required to make an impact. Not only these products look good, they also convey a sense of class and quality.

There are two ways you can use metallic finish for your printed merchandise – Metallic Foil Stamping and Metallic Ink Printing. While both of these techniques are used to enhance the aesthetics and give a shiny gleam to your prints, they differ a lot, both in process and the end result.

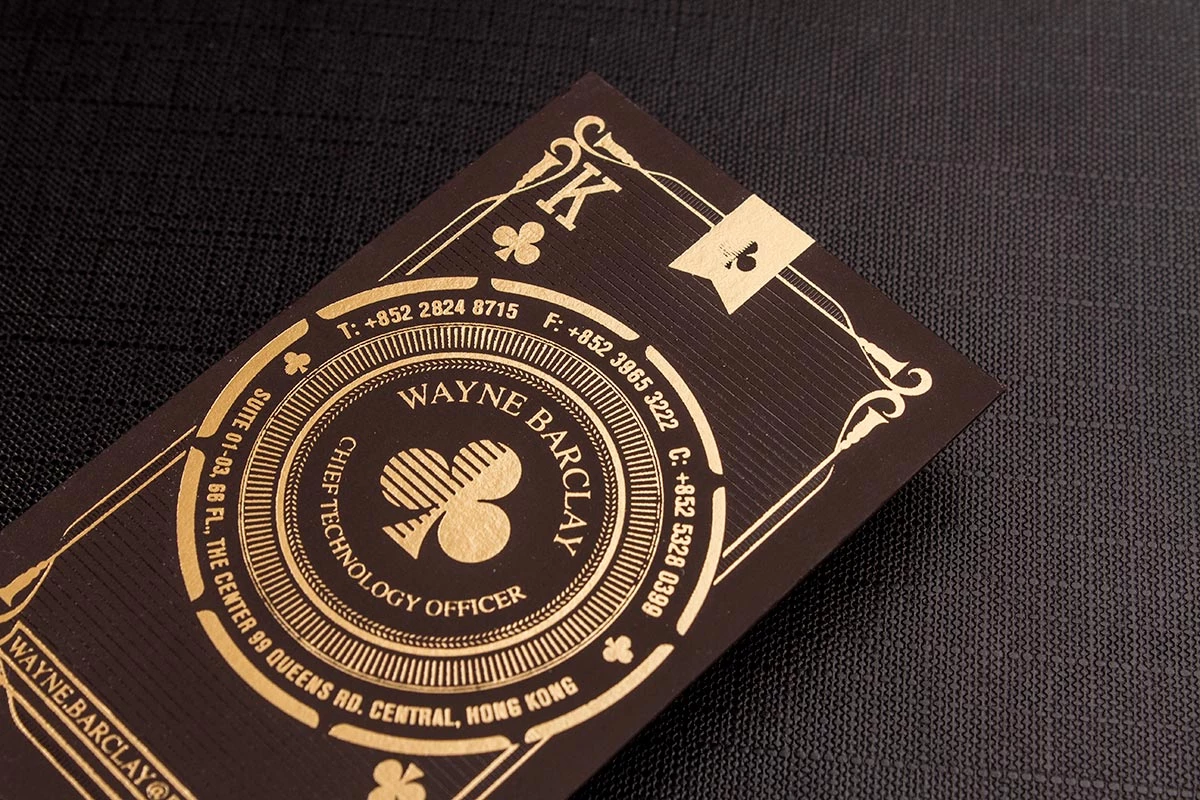

Metallic Foil Stamping, as the name suggests, is the process of impressing a foil onto your stock through heat and pressure. To put simply, it means attaching a foil onto the surface of your choice which not only gives it a unique look, but texture as well.

On the other hand, Metallic Ink Printing is an entirely different process. It uses a special type of ink that is mixed with actual metal particles, giving it a metallic shiny look. The ink is first used in the printing process, but to get the desired effect, it may require subsequent coats as well.

But is really better than the other? Let’s find out.

Shiny Finish: Out of the two, metallic foil stamping provides an overall shinier finish than ink printing as it is the last thing to be attached to the surface while metallic ink will need multiple coats that can mess up the existing design.

Subtle Finish: If you are looking for subtlety, go with metallic ink printing. You can adjust the prominence of the ink in relation to its background and the overall design to create a beautiful final product.

Best for Embossing: This one has to go to foil stamping because it works amazingly well with embossed elements as compared to ink printing. Ink printing tends to crack sometimes if it’s embossed (due to the presence of metal in the ink) and can ruin the design.

Best for Colour Variety: Ink printing takes this one, hands down. Although both foil stamping and ink printing offers a variety of colour choices, ink printing is miles ahead as it is actually a mixture and can be changed to suit a wider colour spectrum.

Durability: Foil stamping is more durable and has a far longer lifespan than Ink Printing. This is due to the presence of metallic particles in the ink which can become brittle over time. That’s why metallic ink requires a coating on top to last longer or else it can give a cracked ink effect.

Least Expensive: Metallic ink printing is more cost-effective and less expensive than foil stamping. If you compare both the processes, you will find that ink printing is generally cheaper than foil stamping.

There is no better or the right way to give a metallic finish to your stock. Both these processes have different features and shortcomings. Which one is better will entirely depend on your requirements and the end result you’re looking for.